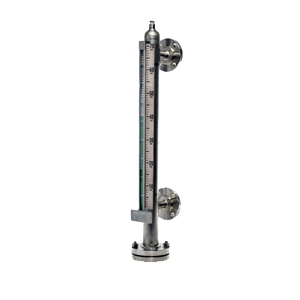

Magna-Site™ Magnetic Level Gauge

The KENCO Magna-Site is a magnetic level gauge used to determine the volume of liquid contained within a tank. Because the Magna-Site eliminates the need for glass, high pressure applications and hazardous locations are protected from the danger of a chemical spill due to glass failure.

The KENCO Magna-Site utilizes three major components: the gauge housing chamber, the magnetic float, and the magnetic flag assembly (Indicator).

The gauge housing chamber is typically mounted adjacent to the side of the tank. It is constructed to withstand the same temperatures and pressures as the tank itself. It is equipped with the appropriate tank mounting connections for easy installation and to allow equalization of liquid level in tank and gauge.

Inside the gauge housing chamber is the magnetic float, which contains radially-positioned magnets to provide a 360 degree magnetic flux field. Each float is internally weighted based on specific gravity so that the liquid level in the gauge coincides with the location of the magnets inside the float.

Attached to the gauge housing chamber is the magnetic flag assembly. This is the visual means of liquid level indication for the KENCO Magna-Site. The assembly is made up of a series of bicolored, fluorescent flags. As the magnetic float rises and falls with the liquid level in the gauge housing chamber, a magnet embedded in each flag reacts to the 360 degree magnetic flux of the float. This magnetic interaction causes each flag to rotate 180 degrees. The flags below the magnetic flux of the float will flip to fluorescent green, while those flags above the float level remain bright white. Other colors are available upon request (red/white, black/yellow, blue/white).

When your application priorities are safety, visibility, and accuracy, the KENCO Magna-Site is the low-maintenance, cost-effective solution.

Additional documentation

Below you can download the following documentation:

Installation Instructions:

Related Documents:

Features

- Maximum safety – No glass is used in the construction.

- Optimum visibility – Fluorescent flags are visible from great distances

- Float with 360° magnetic flux – Maintains a strong magnetic field in all directions; turbulent liquids will not cause flag assembly to give an inaccurate level indication

- Double flag protection – Flags are hermetically sealed inside a PTFE encapsulated assembly which is shrouded by a 300 series stainless steel enclosure on three sides with a UV stabilized high-impact clear polycarbonate shield

- Adjustable viewing angles – Flag assembly can be rotated to any angle to provide maximum visibility

- Multiple mounting options – Engineered construction allows for a variety of mounting configurations

- Compatibility – A broad range of materials can be used to withstand harsh chemicals

- Remote level indication – Explosion-proof magnetostrictive level sensor/transmitter provides an output signal via Analog (4-20mA) with HART®, Modbus RTU (Remote Terminal Unit) or DDA (Direct Digital Access)

- Height scale – 304 stainless steel with no. 3 finish and large etched characters/lines for easy reading

- Convenience – Easy installation and very low maintenance

- Warranty – Two year guarantee against defects

- Reliability – KENCO has been building magnetic liquid level indicators since 1985

- Compliance with the requirements of ASME code for pressure piping, process piping, B31.3

- Certificate of Authorization including CRN numbers issued by Alberta Boilers Safety Assn. for use in Canadian provinces and territories

Industries served

- Chemical and Petrochemical Refineries

- Water and Waste Treatment

- Pulp and Paper Processing

- Power Plants

- Pharmaceutical Processing

- Food and Beverage Processing