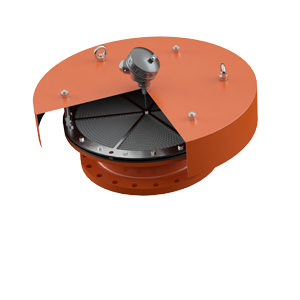

ESA Series Flame Arrester

Principles of Operation

Elmac Technologies® ESA Series of End-of-Line Deflagration Arresters are designed to be installed at the end of a pipeline or exit vent from a vessel, where the ignition source is external. This provides protection against atmospheric deflagrations and short-time burn events.

In the event that a flame stabilises on the arrester element, the sudden increase in temperature would be detected by a control/monitoring system. In these circumstances secondary protection measures such as the purging with inert gases, or the activation of shut-off valves, would be implemented. For a deflagration with no stabilised flame, the combustion products are cooled at the element surface by heat dissipation. This prevents continuation of the combustion process through the arrester and into the protected vent line.

The ESA Series incorporates Elmac’s E-Flow™ crimped ribbon technology in the flame arresting element. The metal matrix of the element has been optimised, using Computational Fluid Dynamics, to ensure industry-leading flow and pressure drop characteristics.

Explosion Groups

Elmac ESA Series of End-of-Line Arresters are ATEX certified for gas explosion groups IIA1 & IIA at a maximum operating temperature of +150°C

Additional documentation

Below you can download the following documentation:

Product Specifications

- Short-time burn rated for protection from stabilised burning events

- Extended upper operating temperature limit

- Exceptional flow capacities with minimal pressure drop

- Easy-clean, replaceable, crimped-ribbon elements

- Unique element design is less susceptible to fouling/clogging

- Light-weight for ease of installation