Explosion Venting

In explosion protection, it’s not just about selecting the right panel — it’s about understanding the underlying principle: explosion venting.

This process ensures that the pressure from an explosion is released in a controlled way, preventing structural damage and safeguarding both personnel and equipment.

While the Explosion Panels & Relief Panels page explains the different types of panels available, here we focus specifically on how the venting process itself works and why it is essential for industrial safety.

What is explosion venting?

Explosion venting is a safety mechanism in which a panel ruptures when the pressure inside a vessel or system rises rapidly due to an ignition or reaction. This allows the pressure wave to be safely released without damaging the equipment.

Rather than absorbing the energy inside the system, explosion venting redirects it outwards. This prevents tanks, silos or duct systems from rupturing or collapsing entirely.

How does it work in practice?

The process of explosion venting can be divided into three stages:

- Pressure build-up – A rapid increase in pressure occurs due to an ignition or chemical reaction.

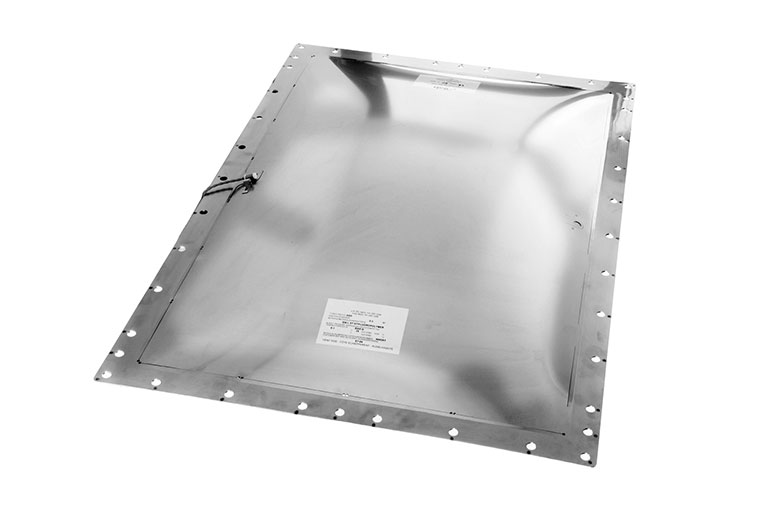

- Panel rupture – The explosion panel is designed to open at a specific burst pressure.

- Pressure release – Excess gases and energy are vented outside, protecting the installation.

The effectiveness of this process depends heavily on the correct placement and design of the explosion panels.

Read more about the different panel designs on the page Explosion Panels & Relief Panels.

Typical applications

Explosion venting is used in a wide range of industrial processes, including:

- Silos and storage tanks – protection against dust explosions from grain, sugar or wood dust

- Dust collectors – common hotspots for dust explosions in the food industry

- Reactors and pressure vessels – securing chemical processes with fluctuating pressures

- Piping systems – controlled pressure release in complex pipe networks

By safely directing pressure outwards, explosion venting helps limit equipment damage and minimises process downtime.

Key benefits

- Maximum safety – protects installations and personnel

- Cost savings – prevents severe damage and long downtime

- Proven concept – simple but highly effective technology

- Standards compliant – meets ATEX and NFPA 68 requirements

Explosion venting is a proven and highly effective method for protecting industrial installations from the effects of explosions. By understanding the process and selecting the right panels, you can improve safety, reduce downtime and ensure compliance with international standards.

Want to know how explosion venting can protect your installation?

Contact Delta Engineering B.V. for expert advice and tailored solutions.