Industry Applications

No two industries are the same — the risks in a chemical plant are very different from those in a grain silo or power station.

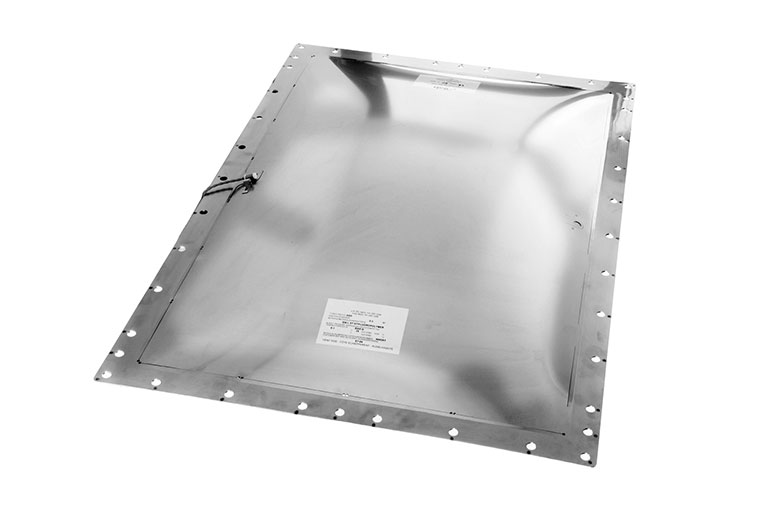

Explosion vents provide an effective way to protect equipment and personnel from the consequences of an explosion in all these sectors.

While the Explosion Vents page explains what explosion panels are and how they work, here we focus on the practical side: how they are applied across different industries and what benefits they deliver in each sector.

Chemical industry

The chemical industry involves flammable gases, liquids and powders. Even small errors or pressure build-ups can lead to major explosions.

Typical applications:

- Reactors and pressure vessels

- Solvent storage tanks

- Vapour and dust filtration systems

Key benefits: Improved safety, ATEX compliance and minimised production losses in case of incidents.

Oil and gas sector

The oil and gas sector carries high risks due to flammable gases and high operating pressures. Explosion vents are used in systems where the risk of explosion is constant.

Typical applications:

- Compressors

- Gas treatment installations

- Piping systems and pumps

Key benefits: Rapid pressure relief, reliable performance under extreme conditions and reduced costly downtime.

Food industry

Dust explosions are one of the biggest hazards in the food industry, especially with materials like grain, sugar, cocoa and milk powder.

Typical applications:

- Silos

- Dust collectors

- Pneumatic conveying systems

Key benefits: Protection against dust explosions, preservation of product quality and compliance with strict hygiene standards.

Pharmaceutical industry

The pharmaceutical industry requires ultra-clean and strictly controlled production environments. Explosion vents are often used in hygienic designs to ensure cleanability.

Typical applications:

- Production reactors

- Dust filters in cleanrooms

- Transport and storage systems

Key benefits: Guarantees safety without compromising hygiene, minimises contamination risks, fully compliant with relevant standards.

Energy and metal industries

High temperatures, flammable materials and combustible dust are common in the energy and metal sectors.

Typical applications:

- Power plants

- Coal and biomass processes

- Metal dust extraction and filtration systems

Key benefits: Robust solutions, reliable performance in harsh environments, protection of critical infrastructure.

Why industry-specific applications matter

Each industrial process comes with unique risks and requires tailored solutions. Selecting the right explosion vents per industry is essential to ensure safety, compliance and operational continuity.

For more information about legal requirements, see our page on Regulations & Standards.

Explosion vents are used across a wide range of industries — from chemicals to food, and from oil & gas to energy.

Each sector, however, requires a solution tailored to its specific risks and processes.

Want to find out which solution fits your industry best?

Contact Delta Engineering B.V. for personalised advice and a customised solution.