Innovations and Technological Developments in Rupture Discs

The technology behind rupture discs is constantly evolving to meet the growing demands of modern industrial processes. On our main rupture disc page, we discussed their basic functions. In this section, we focus on the latest innovations and trends that enhance the performance and functionality of rupture discs.

Benefits and Applications

Improved Performance: Innovations result in more accurate and reliable rupture discs.

Cost savings: New technologies can lower maintenance costs and downtime.

Sustainability: Developments focus on eco-friendly materials and production processes.

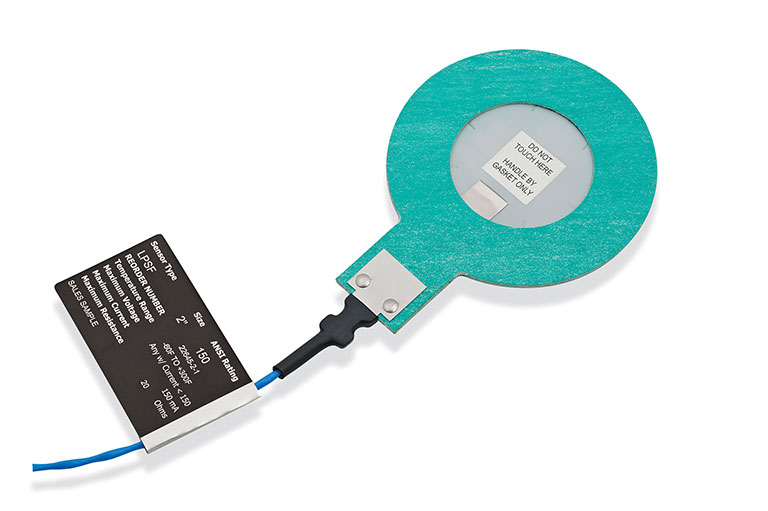

Integration with Industry 4.0: Innovative rupture discs now feature sensor technology, making them part of advanced process control systems. These smart rupture discs provide real-time data on pressure and status, enabling predictive maintenance and more efficient operations.

Technical Details and Specifications

1. Advanced Materials

- Metal Composites: a composition of two materials results in rupture discs with enhanced mechanical properties and corrosion resistance.

- Ceramic Rupture Discs: Suitable for extremely high temperatures and aggressive chemical environments, offering an alternative to traditional metal rupture discs.

- Graphene-Reinforced Materials: Utilizing graphene can create thin, lightweight rupture discs with high strength.

2. Smart Rupture Discs

- Sensor Integration: Built-in sensors provide real-time data on pressure, temperature, and disc status.

- IoT Connectivity: Wireless communication enables integration into industrial networks, facilitating predictive maintenance and rapid response.

- Self-Diagnostic Functions: Smart rupture discs can detect anomalies and send alerts before issues arise.

3. Additive Manufacturing (3D Printing)

- Custom Designs: 3D printing allows for rupture discs with complex geometries unattainable with traditional methods.

- Faster Prototyping: Speeds up the development of new rupture disc designs, fostering innovation.

- Material Optimization: Enables the use of advanced materials specifically tailored for certain applications.

Stay ahead with the latest technological advancements in rupture discs. Delta Engineering B.V. is here to help you apply these innovations to your processes, enabling you to benefit from improved safety, efficiency, and cost savings.

Contact us to discover how our innovative solutions can strengthen your business.